Why Prep Your Concrete Before Epoxy?

If you want to enhance your concrete’s look and durability, then choosing an epoxy or concrete coating can get the job done. Preparing your concrete surface properly is crucial for achieving a durable and long-lasting epoxy flooring finish, however. In this guide, we’ll explore the best methods to prep your concrete for epoxy application, ensuring optimal adhesion and performance.

Prepping your concrete surface before applying epoxy is essential for ensuring a successful and long-lasting flooring finish. Proper preparation removes surface contaminants, opens up the pores of the concrete, and creates a textured surface profile that enhances the adhesion of the epoxy coating. Without adequate prep, the epoxy may fail to bond properly to the substrate, leading to issues such as peeling, bubbling, or delamination.

Concrete Preparation Methods

While it may be tempting to skip surface preparation, especially if the concrete appears to be in good condition, it’s essential to note that proper prep is key to a successful epoxy installation. Neglecting surface preparation can result in poor adhesion and premature failure of the epoxy coating.

Acid Etching

This process involves applying a diluted acid solution to the concrete to remove surface contaminants and open up the pores of the substrate.

Water Jetting

Water jetting is a surface preparation method that utilizes high-pressure water jets to remove contaminants, coatings, and surface irregularities from concrete surfaces.

Scarifying

Scarifying involves mechanically abrading the surface of concrete using rotating cutting tools, such as scarifiers or milling machines.

Rotomilling

Rotomilling, also known as cold milling or asphalt milling, is a process used to remove existing asphalt or concrete surfaces to a desired depth. This method utilizes a rotating drum with cutting teeth to grind and pulverize the surface material, leaving behind a roughened substrate suitable for resurfacing or overlay applications.

Scabbling

Scabbling is a mechanical surface preparation method that involves chipping or hammering the surface of concrete to remove coatings, laitance, and surface irregularities.

Hammering

Hammering, or pneumatic chipping, is a manual surface preparation method that uses handheld pneumatic tools, such as chipping hammers or jackhammers, to remove coatings, adhesives, and surface imperfections from concrete surfaces.

Surface Retarding

Surface retarding is a chemical surface preparation method used to expose aggregate in freshly placed concrete. This process involves applying a retarder to the surface of the concrete shortly after placement, which delays the setting of the cement paste and allows for selective removal of the surface layer to reveal the underlying aggregate.

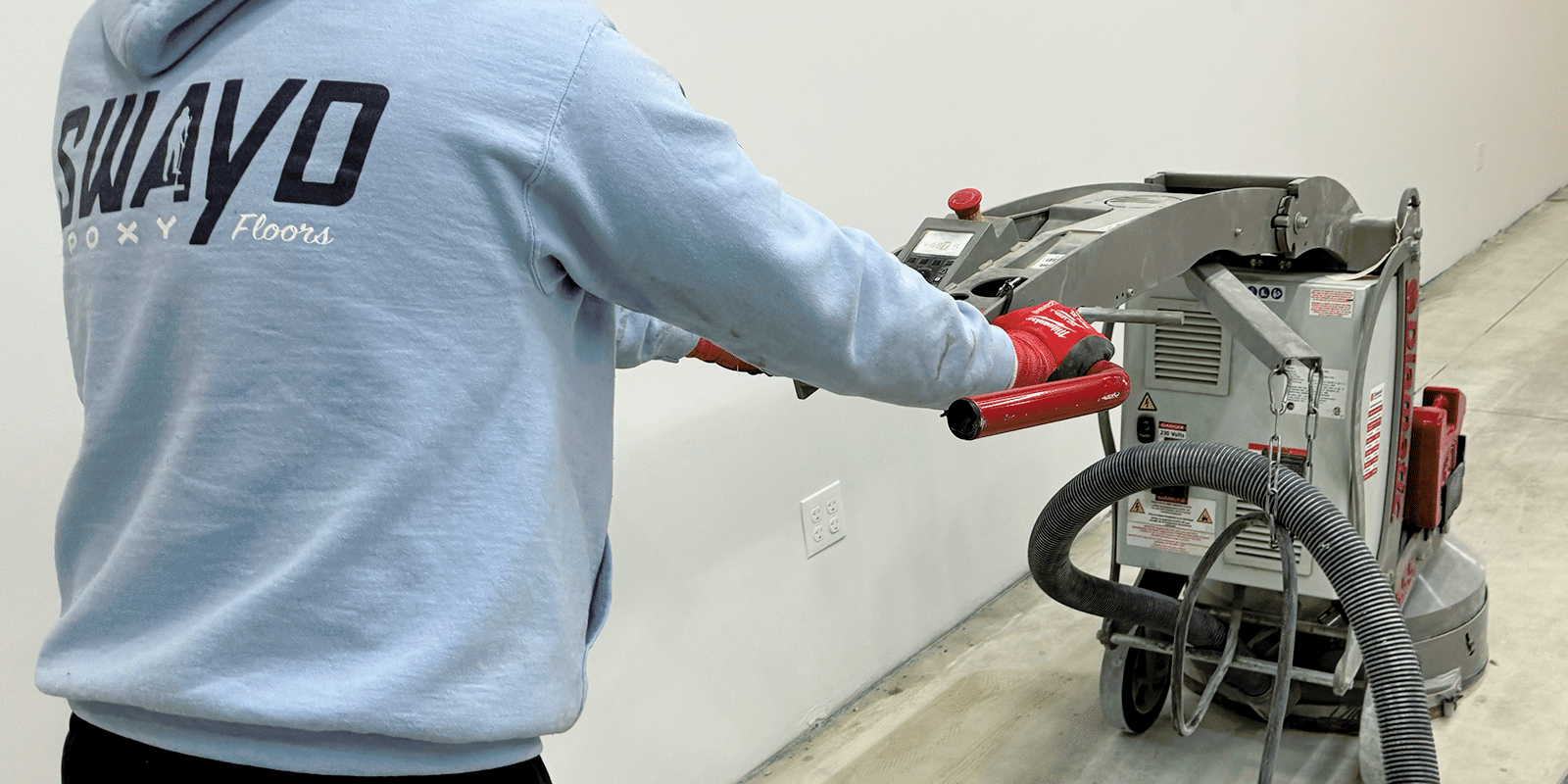

The Swayd Way: Grinding & Shot Blasting

At Swayd, we have seen the difference proper concrete preparation makes vs. no prep or an acid-based option. For the best durability, look, feel, and longevity – our team at Swayd uses grinding, but we also recommend shot blasting as another great option.

Shot Blasting vs. Grinding

Grinding

Grinding is a mechanical surface preparation method that utilizes specialized equipment, such as diamond-grinding machines, to remove surface irregularities and create a smooth, uniform substrate. Grinding is particularly effective for removing existing coatings, adhesives, and imperfections from the concrete surface, ensuring proper adhesion of the epoxy coating.

Shot Blasting

Shot blasting is a highly efficient method of concrete surface preparation that is ideal for large-scale projects and industrial applications. This process involves propelling small steel shot or abrasive media at high velocity onto the concrete surface to remove contaminants and create a textured surface profile. Shot blasting promotes optimal adhesion of the epoxy coating and ensures a durable finish.

Trusted Concrete Prep and Coatings

By investing time and effort into concrete prep, you can ensure that your epoxy flooring not only looks great but also performs reliably for years to come. If you have questions about preparing your concrete for epoxy or a coating, get in touch with our team at Swayd. We can give you advice, and estimates, and ensure that your concrete will last. Take your concrete – whether in a garage, on a patio, or in a warehouse – to the next level with Swayd.