In this industry, flooring is critical for maintaining a clean, safe, and efficient environment. This job shows how epoxy floor coatings meet these demanding standards. It involved merging two separate spaces and installing a seamless, durable epoxy floor system designed to withstand heavy equipment, resist chemical spills, and uphold strict cleanliness requirements.

The Challenge: Combining Two Areas

Our client needed to merge two separate spaces that were divided by a half wall. The existing flooring included some vinyl tile, and removing the wall left a noticeable gap in the floor. The project required a solution that would create a seamless, durable surface suitable for pharmaceutical manufacturing.

Our Approach

We began the project by carefully evaluating the space. Our team measured the area, checked concrete hardness and moisture levels, and identified repair needs. This detailed planning ensured we had the right materials and approach for the project.

To tackle this commercial epoxy flooring project, we first addressed the floor repair. We fixed the gap left by the removed wall and remedied any other imperfections in the concrete. Next came surface preparation, a crucial step in ensuring proper epoxy adhesion. We used our diamond grinder to prepare the entire floor area, creating the foundation for a long-lasting bond.

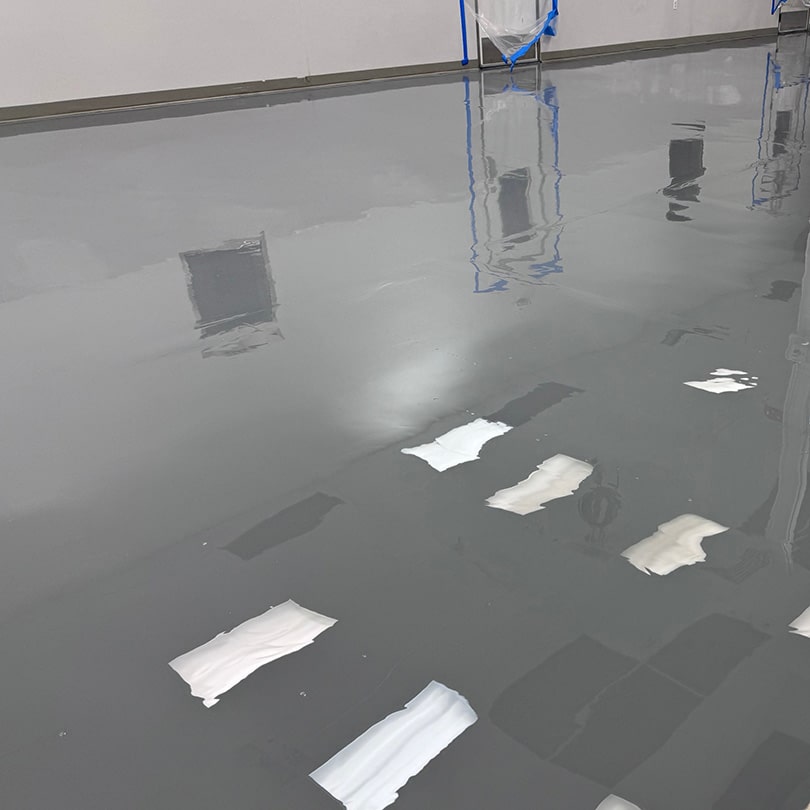

To prevent future issues, we applied a moisture vapor barrier epoxy. This layer protects against potential moisture problems that could compromise the epoxy floors. We then applied our high-quality solid epoxy in a sleek gray color, matching the client’s previous flooring but providing a fresh, uniform look.

For the finishing touch, we added a polyaspartic top coat, enhancing durability and providing a beautiful shine. As an added safety feature, we mixed aluminum oxide into the top coat, creating a slip-resistant surface – a crucial consideration in any industrial setting.

A Pharmaceutical Floor That Delivers

The change was clearly visible. What was once two separate spaces with worn-out, faded flooring became a single, unified area with a glossy, durable surface. The new gray epoxy floor looks professional and clean while meeting the requirements of a pharmaceutical manufacturing environment.

Our solid epoxy solution offers several benefits for this type of facility. The seamless surface is easier to clean and maintain, which is crucial for pharmaceutical standards. It also provides chemical resistance, standing up to spills and harsh cleaning agents. The durability of the epoxy floor coating allows it to withstand heavy foot traffic and equipment movement. Finally, the added traction from the aluminum oxide enhances safety by reducing slip hazards.

Exceeding Expectations

This project in Lakewood shows what we do best – providing tailored epoxy flooring solutions that meet our client’s specific needs. Whether it’s a large-scale industrial project or a residential garage, we bring the same level of expertise and attention to detail to every epoxy floor coating job.

Are you considering upgrading your facility’s flooring? Whether you’re in the pharmaceutical industry or any other field requiring durable, attractive epoxy floors, we’re here to help. Get a free estimate and see how we can improve your space.